Medieemballage i metal

Glud & Marstrand A/S / / Produkt design / / 2002-3

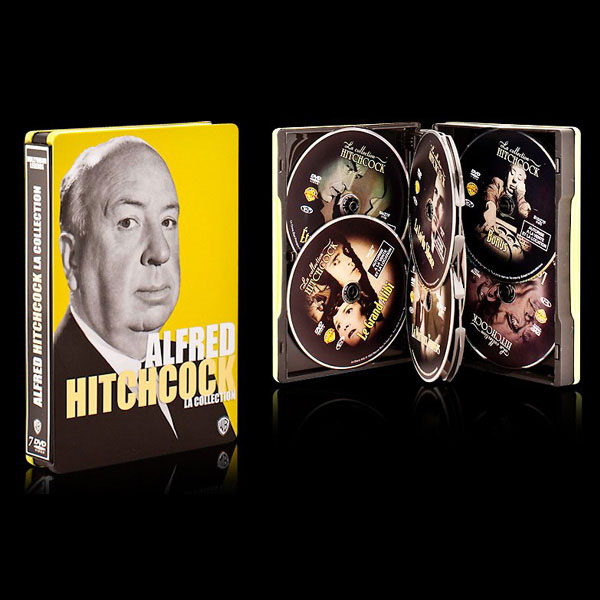

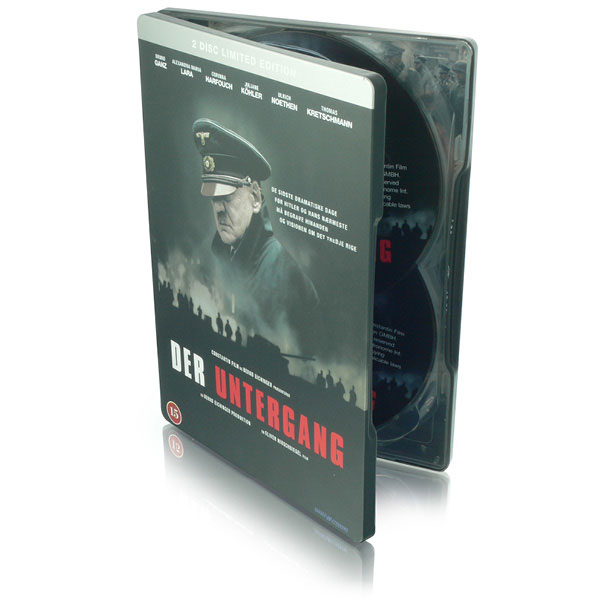

Udvikling af medieemballage i metal til DVD’er, software og senere Blu-Ray. Produktet er blevet en stor succes og produceret i et stort 3-cifret milliontal.

SteelBook emballagen blev udviklet for at øge den oplevede værdi af produktet indeni. Da SteelBook blev udviklet i 2002 fandtes der både metal- og plastikemballager, men plastikemballagerne så billige ud og metalemballagerne manglede funktionalitet. Ideen bag SteelBook er at kombinere det bedste fra 2 verdener. Metal til udseendet (muligheden for at dekorere både ind- og udvendigt) og plastik til funktionaliteten (hængsler, mediefiksering, ryg, kliklås etc.)

Vandt 2.prænie i kategorien: ” Promotional ” i “Can of the Year Awards 2005″

Vandt 1.præmie i kategorien: “Consumer Packagings” i “Starpack Awards 2005″

Mediapackaging in metal

Development of media packaging in metal for DVDs, software and later Blu-Ray. The product has been a great success and produced in a large 3-digit millionth.

SteelBook was designed to increase the percieved value of the product it was selling. When we designed the SteelBook in 2002 there existed plastic packaging and metal packaging but the plastic packaging looked cheap and the metal packaging lacked functionality compared to the plastic packaging.

So when SteelBook was designed it was a combination of the best from 2 worlds. Metal for the looks (and ability to print both external and internal in the packaging) and plastic for the functionality (hinges, dischubs, booklet fixture, click opening etc.

Won 2nd prize in the category: “Promotional” in the “Can of the Year Awards 2005 ″

Won 1st prize in the category: “Consumer Packagings” in the “Starpack Awards 2005

Patents

EP1705662 (A2) – A metal packaging

DK1636800 (T3) – A METAL PACKAGING

HK1084229 (A1) – A metal packaging

AT341928 (T) – METALLKAPSELUNG

BRPI0408445 (A) – embalagem

CN1751354 (A) – A metal packaging

JP2007238185 (A) – PACKAGING AND RETAINING MEMBER

PT1636800 (E) – A METAL PACKAGING

NO20053433 (A) – Metallinnpakning

SteelBook – the original story

(Written approx. 2005)

Two young upcoming Scandinavian industrial designers are responsible for the SteelBook design: Niels Toft Jørgensen and Mazyar Abolfazlian. Their revolutionary design creates a completely new range of opportunities for the media industry

The SteelBook is a result of considerations that have been going on at Glud & Marstrand for years. The SteelBook project was kicked off at a meeting in September 2002, where the possibilities for taking advantage of the company’s know-how to create metal media packaging were discussed. In this article, the two designers Niels Toft Jørgensen and Mazyar Abolfazlian tell us what happened then.

Our goal was to fill an empty space in the media market by raising the ‘perceived value’ – the imaginary value connected to purchasing – of a product. Games, software, movies and music are often expensive but the actual products are sold in plastic packaging that rarely looks good. We wanted to develop a container that makes the customer feel like he is getting more for his money. This is why we have focused on how the product feels in the hand, the sound and the sensation when it is opened. At the same time it had to look good on the shelf, in the book case or on the table.

When the general goals had been established they were followed by a number of brainstorming meetings. The meetings resulted in numerous sketches and computer drawings, which all revolved around digital storage media. We selected a few concepts, which we then split between us, went home and continued working on them alone. When we met up again we made a list of what was good or bad about each idea – and what was possible for us to produce.

The entire development process took place in a close, organic co-operative effort, where we constantly investigated new design ideas with Glud & Marstrand’s experienced engineers, and checked if they could hold water. More often than not they didn’t. For example, we experimented with folding the metal, which opened up for a wide variety of design options. This resulted in a flow of design ideas, which were produced in co-operation with both internal and external partners.

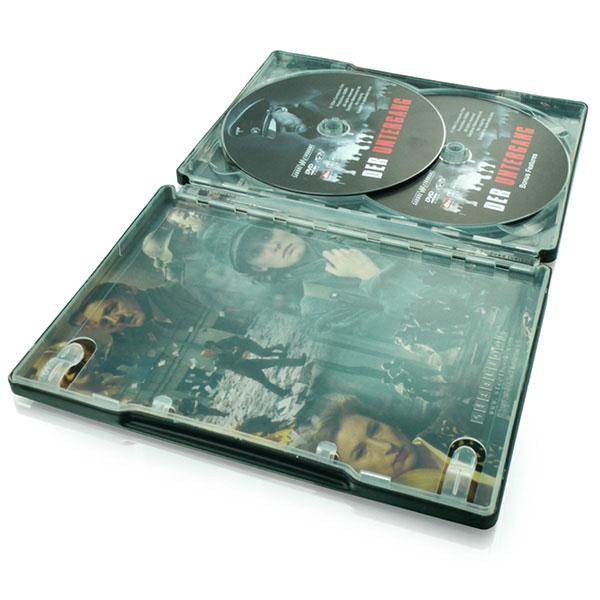

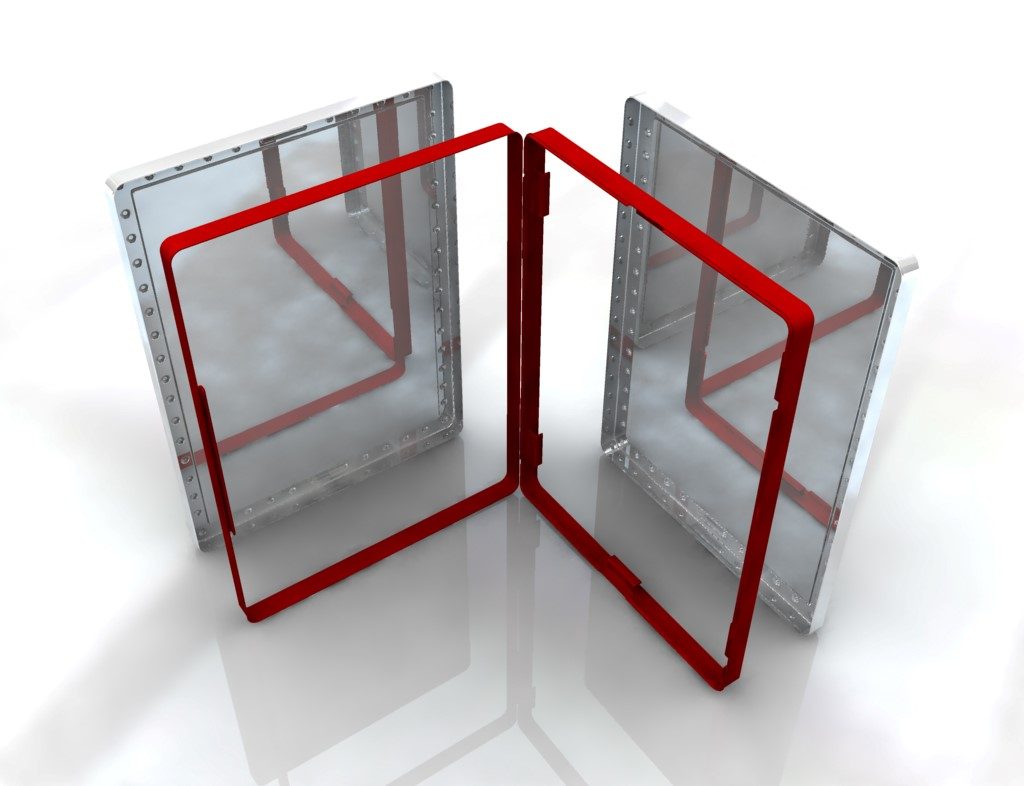

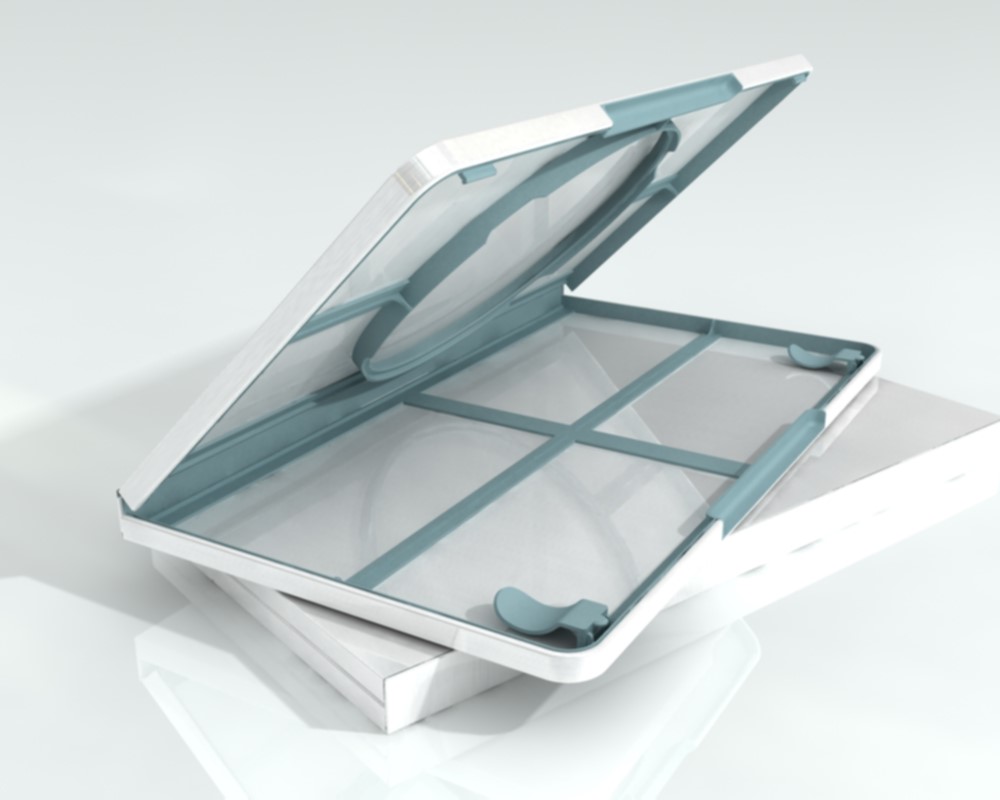

In early 2003 it was clear that the SteelBook would be made out of a combination of plastic and metal. Metal on the outside to give it the exclusive look and feel that is one of metal’s unique qualities. Plastic on the inside to provide the SteelBook with the relatively complex mechanical features: hinge, disc fixture, booklet fixture and more.

All that remained was to make all the ends meet:

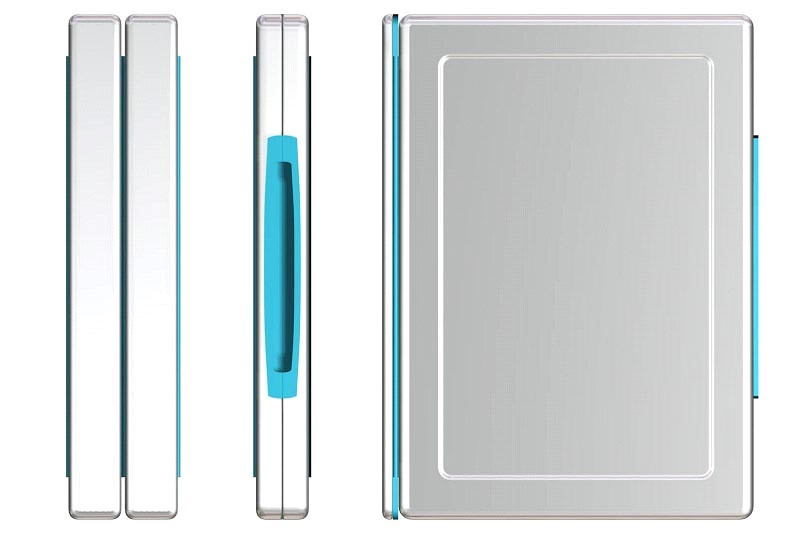

• A complete metallic outer surface

• A fully decorated back with the ability to open 240 degrees

• Compliance with existing DVD box outer dimensions without restricting internal space

• Opening geometry that emulated standard DVD packaging

• The opening grip needed to be adapted to existing packing machinery

• Full visibility of internal decoration of the metal case through a transparent inner plastic part

In June 2003 we made the final design breakthrough and stood with a complete SteelBook concept. Now we knew that the front and back of the SteelBook had to be deep drawn and then shaped, and that the geometry of the plastic on the inside was more or less determined.

Apart from the opening grips, which consist of plastic that has been extended through the inner plastic parts we had achieved a fully metallic expression without limiting the opening geometry so much that automation was impossible. What remained was work on the design within the framework that had been a result of the mechanical construction.

The SteelBook Takes Shape Soon it became clear that the SteelBook had an unacceptable mechanical weakness at the exact same place as we perceived it to have its greatest aesthetic weakness: the opening grip.

In the transition from metal to plastic a weakness would invariably develop in the metal that would make it susceptible to deformation as a result of normal use.

We knew that the best solution, both mechanically and aesthetically would be to shape the grip in metal. However, such a solution demands so much of the shaping process that we initially gave up on it.

The final SteelBook design proves that we have succeeded in developing a production process that can handle such intense and critical manufacturing of the metal shells.

Now the box has been shaped with a smooth rounded curve that enables your fingers to grip and open the box. We took advantage of the metal’s strength and at the same time achieved a completely metallic look.

The SteelBook Designers

Niels Toft Jørgensen (b. 1975), industrial designer, Cand. Arch.

Niels took his master’s degree at the Aarhus School of Architecture in 2000. Today Niels works for several large companies, such as Grundfos and Bang & Olufsen, where he is attached to the development department as concept developer. Niels took Glud & Marstrand in as his first customer back in 1997.

Mazyar Abolfazlian (b. 1970), industrial designer, Cand. Arch.

Mazyar holds a master’s degree from the Aarhus School of Architecture (1999). He has worked on projects for Alfa Romeo in Italy and has also designed lighting, furniture, office supplies and fittings. Some of his recent furniture designs have been exhibited at the ICFF in New York in 2004.